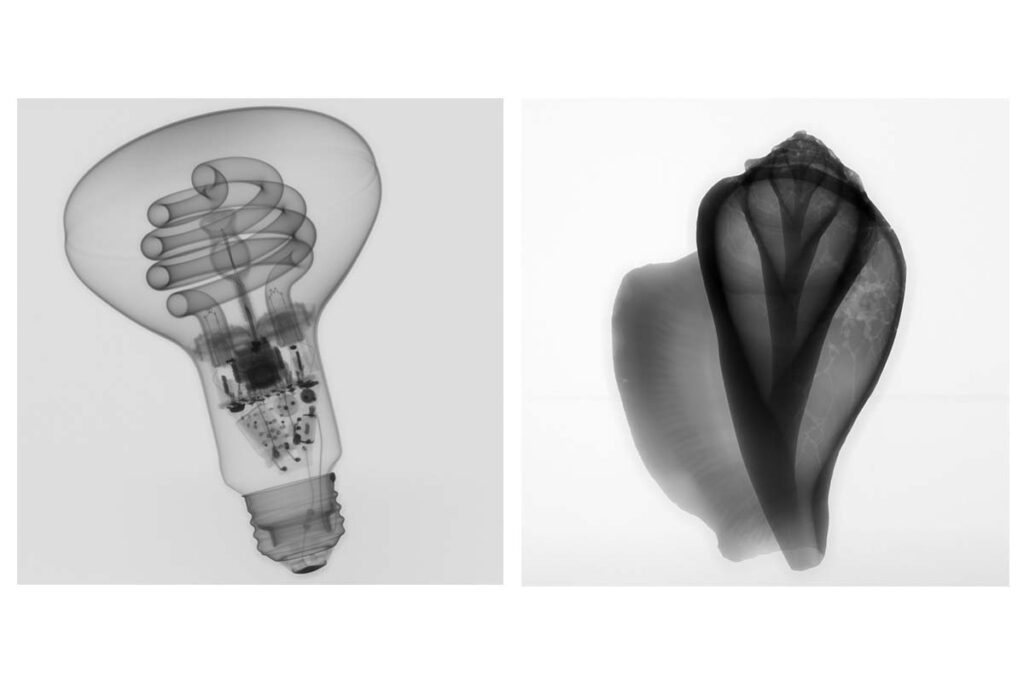

X-ray computed tomography (CT) is a non-destructive imaging technology that allows the user to view, analyze, and measure internal and external structures of components without the need for cutting or disturbing the part. Industrial CT scanners use a powered x-ray source, rotational stage, and an x-ray detector to generate a 360-degree series of hundreds to thousands of angular projections, or radiographs, and these radiographs are reconstructed into a three-dimensional volume during post-scan processing. The final product can be viewed as a 3D volume object or in two-dimensional slices and analyzed in a number of ways, including for dimensional measurements and analysis, defect detection, and material/density information.

The primary advantage of CT is the ability to analyze hidden or non-accessible features and geometries precisely, non-destructively, and relatively fast compared to traditional measuring machines like tactile CMMs. CT data can also be used to create detailed animations and as part of the reverse engineering process – converting a 3D volume to an STL model for 3D printing. CT technology can be applied to a variety of different parts, from metals to plastics to fossilized materials, and the technology is being used today across industries from aerospace to archaeology.